704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

2113 Results Found

704-841-2001

NORTHTECH NT 1000-50HCVS Single-Sided 40" PlanerSpecifications: -- 40" Planer, 40 HP main motor, Helical Head, Adjustable bed rollers 15 mm x 15 mm x 2.5 mm Carbide Insert cutters. -- The spiral cutterhead provides a high chip removal rate, superior surface finish and low noise. -- Powerful 40 HP cutterhead motor makes this planer ideal for heavy-duty planing and meets high production requirements. -- Variable feed speed is mechanical variable from 0 - 90 FPM. -- Power elevation of the feed bed with "727 M Digital Table Adjustment" for fast accurate, and convenient thickness setting. -- Extra heavy rib reinforced cast iron table, surface precision ground. Equipped with: -- (4) Powered steel bed rollers. -- (4) Upper rollers. -- (2) Powered corrugated infeed rollers. -- (2) Powered urethane outfeed rollers. -- Upper and lower limit switches for opening control. -- (4) Dual 50 mm jack screws for raise/lower bed movement; 12" max opening. -- 2 HP Elevation motor with manual adjust. -- Rear E-Stop for added safety. -- Dual 6" dust ports requiring 1,000 CFM @ points of extraction.

Call for Price

NORTHTECH NT 400EL Double Head 16" PlanerHeavy Duty Chain Drive Series Double SurfacerSpecifications: --15 HP Top, 15 HP Bottom Head Motor -- Dual (6) Row Helical Cutterhead with four sided 15 x 15 x 2.5 mm Inserts -- 5,175 RPM solid steel cutterheads with Class 7 NSK bearings -- Cutterhead dimensions: 5"; dia. x 16"; long -- Operating decibel rating of 79 dbProduct Dimensions: -- Working thickness 10 - 155 mm (3/8"; - 6-1/2";) 8 mm min. on request -- 13"; Min. working length -- 16"; Maximum widthFeed System: -- 3 HP Feed motor -- Carpet feeding spike system with (644) spikes -- Feed speed 25 - 85 FPMFeatures: -- 1 HP Elevation motor -- Mechanical variable speed -- Digital control panel with 3 amp meters -- Chrome bed plate 0.01mm (0.004";) thick -- Passline at 32"; -- Amperage requirement: 230V / 115 AMPS, -- (2) 6"; Dust ports requiring 981 CFM @ each point of extraction -- Automatic lubricating system with low level shut off -- UL/CE Certified electrical components -- Includes operator’s manual and parts book -- Net weight: 5,990 Lbs -- Machine / Packed weight: 5,990 Lbs / 6,195 Lbs -- Machine/Packed dimensions (L x W x H): 98"; x 50"; x 70"; / 101"; x 46"; x 80"; -- One year parts warrantyNOTE: All machines are tested stateside prior to shipment providing trouble-free start-up.

$1,450

NORTHTECH NT-6108ES-6 Edge SanderSpecifications: Sanding Belt is powered by a 3 HP 230/460V motor. -- The platen measures 6-3/4″ X 39″ and has NEW graphite. Rubber covered direct drive pulley. -- Equipped with: (1) 7-3/4" x 37" Adjustable side table and (1) 11-1/2" x 19" Adjustable end table; both side & end tables have vertical table travel w/hand wheel adjustment. Complete with: -- Magnetic controls with overload protection & dust hood with 4" dia. outlet.

NORTHTECH - NT-KL-920-PRR- B & NT-KL-920 PRR-U, ...Top & Bottom 3-Head Planer Sander3-Head bottom with: Planer, drum and platen; 3-head top with: Planer, drum, and platen 920 mm (36") wide.Capacity: 36" x 5" thickness.SpecificationsBottom Machine Model: "NT-KL-920 PPR". -- Infeed driven Conveyor: 37" x 72" Long. -- 1st Head: Spiral cutterhead; (8) rows of 15 x 15 x 2.5 mm inserts carbide knives; (4) sides for rotation; low tool cost.Cutterhead: 175 mm (7") Dia. and 50 HP motor. Segmented chip breaker before the cutterhead. -- 2nd Head: Contact roller; (280 mm) 11" in dia.; 70 durometers, powered by a 40 HP motor; running at 3,600 FPM belt speed.Sanding belt size: 85" x 37". -- 3rd Head: 3-1/4" Pneumatic Polishing Platen; engineered as a combination station, air-cushioned & adjustable in pressure to various grits and materials application. Powered by a 30 HP motor. -- Lifting & lowering conveyor bed; 1-1/2 HP motor (includes auto. thickness setup device). -- Variable speed: 7.5 HP; inverter duty motor integrated with an AC inverter (VFD); control providing variable feed rate from 15 - 70 FPM for heavy calibration; LED readout feed speed indicator. -- Microprocessor Control for: Conveyor bed positioning to high precision via keypad entry. -- Automatic electronic preset panel thickness gauge/micrometer. -- Automatic Air Jet blast cleaning system on both sanding heads.Top Machine Model: NT-KL-920 PRR-U -- 1st Head - Spiral Cutterhead: (8) Rows of 15 x 15 x 2.5 mm inserts carbide knives; (4) sides for rotation; low tool cost.Cutterhead: 7" (175 mm) Dia.; 50 HP motor.Segmented Chip Breaker: Before the cutterhead. -- 2nd Head - Contact Roller: 11" (280 mm) Dia.; 70 durometers; powered by 40 HP motor; running at 3,600 FPM belt speed.Sanding belt size: 85" x 37". -- 3rd Head - 3-1/4" Pneumatic Polishing Platen: Engineered as combination station; air-cushioned & adjustable in pressure to various grits and materials application; powered by 30 HP motor. -- Lifting & lowering Conveyor Bed: Motor 1.5 HP (includes auto. thickness setup device). -- Variable speed 7.5 HP inverter duty motor; integrated with AC inverter (VFD) control; variable feed rate: 15 to 70 FPM for heavy calibration; LED readout feed speed indicator. -- Microprocessor Control: For conveyor bed positioning to high precision via keypad entry. -- Automatic electronic preset panel thickness gauge/micrometer. -- Automatic Air Jet blast cleaning system on both sanding heads. -- Powered dropdown Conveyor between Bottom & Top machine.Features (includes both machines) -- Massive monoblock base: 3/4" Thick plate steel weldments. -- Large dia. roller hold-downs; ball bearing supported; 65 duro UV rubber are standard features. -- Automatic soft start of main motors (Y-Delta). -- Disc braking/emergency shut down protection for: Sanding belt breaking, non-tensioned sanding belt; and mistracking of sand belt. -- All motors & electrics are CE-approved. -- Electronic oscillating belt tracking system. -- Au

$34,500

NORTHTECH NT-610EL Top & Bottom Planer:24" Wide x 7.5" thick capacity; 1/4" minimum thickness; 12" minimum stock length.Specifications: -- Cutterheads: 25 HP top head; 20 HP bottom head; 5,800 RPM on cutterheads; (6) row spiral insert cutterheads, Carbide knives 15 mm x 15 mm x 2.5 mm 4-sided -- Feed works: 3 HP variable speed feed with speeds from 20 to 75 FPM; 1 HP motorized raise and lower of bed; DP-525 digital thickness controller; Overhead carpet style feed system Equipped with & Features -- Sectional chip breaker; Hard chrome plated bed; Automatic lubrication for feed system; Amp load meter -- Dust Requirements: 3,800 CFM; (1)10" and (1) 7" dust outlet Seller states this machine has less than 600 Hours of use.

NORTHTECH - NT-SL2000XL, ...Straight Line Rip SawSpecifications: -- 20 HP Direct Drive Straight Line Rip Saw. -- 2" Arbor. -- Distance from column to blade: 18 in. -- Saw blade size: 10" - 14". -- 3-1/8" Cutting capacity. -- Glue Line Saw. -- Feed Motor: 1.5 HP. -- Feed Speed: 20 - 105 FPM.

$59,000

PUTSCH-MENICONI SVP 420 AUTOMATIC TOUCH 2,200 mm x 4,200 mm Automatic Vertical Panel Saw, New with Parts Warranty & Motorized Twin-Blade ScoringSpecifications: -- 2,220 x 4,200 mm (86.61" x 165.35") Cutting cap., 2,080 mm (81.89";) Max. horizontal trim height, 60 mm (2.36") Max. depth of cut. -- Cut tolerance .1 mm over 1 M. -- Main saw: 6 HP - 5,300 RPM Motor with Automatic brake & 250 mm (9.84") Blade Dia. -- Scoring Saw: 1/4 HP Motor & (2) 60 mm (2.36";) Dia. Blades.Equipped with: -- Automatic cut execution. -- Automatic head positioning for horizontal cuts. -- “POSI-SYSTEM"; Automatic positioning stop for vertical cuts. -- Pneumatic automatic shifting frame & THK Linear guides. -- Full-length mid-grid support shelf & Sliding backing panel for thin materials. -- Horizontal repeat strip cutting device. -- Lift-up rollers & Resin-plated aluminum panel support feet, -- Touchscreen Control, with Horizontal & Vertical digital measuring displays.Complete with: -- User Manual. -- 250 mm (9.84") Saw Blade. -- Supplementary Low-Level Stop. -- Extra Short Cutting Device. -- TRK Horizontal Dust Catcher (Configured for independent dust collector).Options available at additional cost: -- Adjustable Thickness Stop. -- Angle Cutting Device. -- V-Grooving Kit, with Adjustable Thickness Stop.

Call for Price

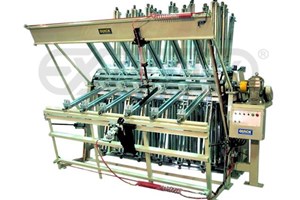

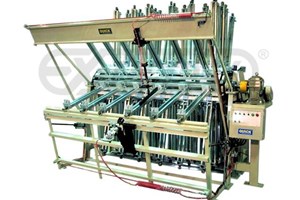

QUICK MACHINERY N-P80 Air Pod style Cold Press. -- Heavy Duty I-beam construction with machined steel plates for flat smooth pressing surface.Specifications: -- Platen pressing area size: 49" x 97" with end loading on 49" side. -- 80 PSI Platen pressure over the entire surface area with 102 PSI supply air pressure. Pressure is applied by 12.8" dia. air pods with 5.9" stroke; (28) air pods total for this size press. -- Air powered raise and lower idler rollers in the bed of the press for loading & unloading panels; raising & lowering of conveyor by control button on panel. -- Motorized Adjustable Daylight Opening from 2" to 40"; push button controls operate an electrically powered chain driven worm gear drive system for precise positioning of upper platen setting/opening. -- Controls: 60-Min cycle timers provide visual and audible signals at the end of each cycle and automatically releases platen air pressure at the end of each cycle if desired. -- Single platen 49" X 97" . -- The press model shown in pictures is a dual platen powered feed through end load press. -- Actual model is N-P80-04-08-EL-1PL-M-40-R-1Z

QUICK 6-Section Clamp Carrier with 16-1/2' width capacity6-Section Pneumatic Clamp Carrier with 16-1/2' width cap. -- (12) Heavy Duty zinc plated clamps per section (72 clamps total); 52" opening on clamps. -- Jaw size of clamps are 3-1/2" high x 4-3/4" wide, with 1° inward draft.Equipped with: -- Pneumatic overhead panel flattener 16-1/2' wide. -- Pneumatic clamp tightener -- Semi-automatic rotation via electric motor drive; -- Separate buttons for Front Rest Out, Rotate Reverse, Rotate Forward, and Front Rest In. -- Flexible conduit for electric wires.Features & Includes: -- Automatic air line oiler; -- High quality urethane finish coating. -- Toolbox with spare parts & tools.Floor space requirement: 236" W X 131"D X 148" H

QUICK 6-SECTION, 10'-1/2' Wide Pneumatic "Standard" Clamp Carrier: 6-Section Clamp typically produces (144) high quality edge glued panels per day (3 panels per section x 6 sections x 8 hours). Equipped with: -- (6) Sections with (8) clamps per section and 10-1/2' width capacity. -- (48) Clamps with 38" opening and 2-1/2" high x 4-3/4" wide jaws with 1° inward draft. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. Features: -- Semi-automatic electric motor drive. -- Pneumatic Panel Flattener for 10-1/2' wide Carrier with easy to use controls. -- Pneumatic Clamp Tightener with 3,000 RPM air wrench is (5 -10) times faster than competitive tighteners; 2-handed, trigger activated tightener is more confidence inspiring than the older, ergonomically awkward "swing-style" clamp tighteners. -- Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality Urethane finish coating, and tool box with spare parts & tools. -- NOTE: Clamp Carrier can be expanded to (14) or (20) sections at a later time. 14-Section Clamp will produce (300) panels per shift; 20-Section machine, (500) panels per shift.

Call for Price

QUICK 20 Section Automatic Clamp Carrier: -- Clamp Carrier: (20) Sections with 8-1/2' width cap., (6) heavy duty zinc plated clamps per section (120 clamps total), 32" opening on clamps (other lengths available). -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- For face gluing, Rocking Plates available as optional equipment. -- Equipped with: -- Fully Automatic Hydraulic Clamp Tightener with adjustable torque limiter, integral Pneumatic Panel Flatteners and Electric Motor Drive with fully Automatic Carrier Rotation Cycle. Two control panels maximize ease-of use. Rack and pinion carriage traverse system is solid and quietFeatures: -- The QUICK Automatic Clamp Carrier is the ideal labor-saving device for the high-production furniture or cabinet manufacturer. The Automatic Clamp Carrier cuts labor costs in half by allowing the Clamp Carrier operator to perform other tasks (such as applying glue to stock, etc.) while the machine automatically flattens panels, tightens clamps, rotates, and loosens clamps. -- After loading wood into a section of clamps, the operator presses the "Auto Tighten" button. The hydraulic Automatic Carriage then traverses from left to right, flattening panels and tightening clamps that it finds along the way. When the Carriage reaches the right end of its traverse, the machine performs an automatic rotation cycle, which brings the next section of clamps down to the operator’s position. The Carriage then traverses from right to left, loosening clamps that it finds along the way. -- The Fully Automatic Clamp Carrier can also be used in manual or semi-automatic modes, by pressing buttons on the Control Panels. -- Complete with & Includes: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: 20 Section machine can produce up to (500) panels per shift!

QUICK 14-Section Pneumatic Clamp Carrier with 16-1/2' width capacity and Glue applicatorWith (15) Standard zinc plated clamps per section (210 clamps total), 48" opening on clamps Standard Features include: Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment (2) Panel Flattener with easy to use controls.(2) Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! Complete with:Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.14-Section Clamp will produce 300 panels

Call for Price

QUICK 40 Section Automatic Clamp Carrier: -- Clamp Carrier: (40) Sections with 8-1/2' width cap., (6) heavy duty zinc plated clamps per section (240 clamps total), 40" opening on clamps with quick adjustment (other lengths available). -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- For face gluing, Rocking Plates available as optional equipment. -- Equipped with: -- Fully Automatic Hydraulic Clamp Tightener with adjustable torque limiter, integral Hydraulic Panel Flatteners and Electric Motor Drive with fully Automatic Carrier Rotation Cycle. Two control panels maximize ease-of use. Rack and pinion carriage traverse system is solid and quietFeatures: -- The QUICK Automatic Clamp Carrier is the ideal labor-saving device for the high-production furniture or cabinet manufacturer. The Automatic Clamp Carrier cuts labor costs in half by allowing the Clamp Carrier operator to perform other tasks (such as applying glue to stock, etc.) while the machine automatically flattens panels, tightens clamps, rotates, and loosens clamps. -- After loading wood into a section of clamps, the operator presses the "Auto Tighten" button. The hydraulic Automatic Carriage then traverses from left to right, flattening panels and tightening clamps that it finds along the way. When the Carriage reaches the right end of its traverse, the machine performs an automatic rotation cycle, which brings the next section of clamps down to the operator’s position. The Carriage then traverses from right to left, loosening clamps that it finds along the way. -- The Fully Automatic Clamp Carrier can also be used in manual or semi-automatic modes, by pressing buttons on the Control Panels. -- Complete with & Includes: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.

QUICK 40 Section 10.5' Heavy Duty Hydraulic Clamp Carrier: -- Clamp Carrier: (40) Sections with 10-1/2' width cap., -- (10) heavy duty zinc plated clamps per section (400 clamps total), 40" opening on clamps with quick adjustment (other lengths available). -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- For face gluing, Rocking Plates available as optional equipment.Equipped with: -- (1) Hydraulic clamp tightener for 10.5' -- (1) Hydraulic clamp tightener 10.5' for second operator -- (1) Pneumatic Panel Flatteners for 10.5' wide -- (1) pneumatic panel fattener 10.5' wide for second operatior -- Electric Motor Drive with fully Automatic Carrier Rotation Cycle.Two control panels maximize ease-of use. Rack and pinion carriage traverse system is solid and quiet -- Complete with & Includes: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.Note: this machine has 2 hydraulic tightener and 2 Pneumatic panel flattener for (2) operator)If one operator is fine the machine price could be reduce by $3,600

QUICK 20" Wide Conveyorized Glue Applicator -- 20" Wide grooved rubber glue applicator roll with stainless steel doctor blade and glue reservoir. -- Features easy adjustment or removal of doctor blade, -- 18' Overall length, 8' infeed before the glue roller and 10' outfeed conveyor. Equipped with: -- Heavy Duty 0.25 HP motor drive for slat-type conveyor and glue roll, limit switch with wand for automatically stopping the slat bed conveyor when stock reaches the Clamp Carrier, adjustable safety slip clutch. Complete with: -- Foot levelers, -- Heavy Duty crossbars, chain guard, high-quality anti-stick urethane finish, and owner & operator's manuals.

QUICK 30-Section Heavy Duty Clamp Carrier with 12-1/2' width capacity -- With (9) Standard zinc plated clamps per section (270 clamps total), 32" opening on clamps.Standard Features include: -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy-to-use controls -- Second Panel Flattener for the second operator -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger-activated tightener is more confidence-inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate the need for manual adjustment of rear clamp jaws. -- Second pneumatic Clamp tightener for the second operator -- Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes the entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly Every time!Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with spare parts & tools.

QUICK 20 Section 16.5' Heavy Duty Clamp Carrier Specifications: -- 20-Section Thick Stock Pneumatic Clamp Carrier; 16-1/2' width cap.; -- (12) Clamps, each with 3 1/2" high jaws and 44" clamp opening for a total of (240) clamps. -- All clamps are heavy duty type; zinc plated and with 1° inward draftEquipped with: -- Dual operator package with (2) pneumatic overhead panel flatteners, -- (2) Pneumatic clamp tighteners. -- Semi-automatic rotation via electric motor drive and separate buttons for Front Rest Out, Rotate Reverse, Rotate Forward and Front Rest In.Standard features: -- Heavy-duty thick stock frame with 3" dia. shafts and 6" I-beam legs; -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with maintenance tools.

QUICK F-CGAP-20-11-17 20" Wide Conveyorized Glue Applicator -- 20" Conveyorized Glue Applicator, 20" wide grooved rubber glue applicator roll and holddown roller with stainless steel doctor blade and glue reservoir.Features: -- Easy adjustment or removal of doctor blade, 30' overall length. -- 11' Infeed before the glue roller . -- 17' Outfeed conveyor. Equipped with: -- Heavy Duty 0.25 HP motor drive for slat-type conveyor and glue roll, limit switch with wand for automatically stopping the slat bed conveyor when stock reaches the Clamp Carrier, adjustable safety slip clutch. Complete with: -- Foot levelers. -- Heavy Duty crossbars. -- Chain guard, high quality anti-stick Urethane finish. -- Owner & operator's manuals.OPTION:Hold Down roll for face gluing 20" wide: $ 700 additional

QUICK 20 Section Heavy Duty Pneumatic Clamp Carrier: -- Clamp Carrier: (20) Sections with 8-1/2' width cap., (6) heavy duty zinc plated clamps per section (120 clamps total), 44" opening on clamps (other lengths available). -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- For face gluing, Rocking Plates available as optional equipment. -- Equipped with: Panel Flattener with easy to use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation: Push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! -- Complete with & Includes: Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: 20 Section machine can produce up to (500) panels per shift!

QUICK 14-Section Pneumatic Clamp Carrier with 8-1/2' width capacity With (6) Standard zinc plated clamps per section (84 clamps total), 32" opening on clamps Standard Features include: -- Clamps jaws are 2-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy-to-use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; a two-handed, trigger-activated tightener is more confidence-inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation; push button, automatic cycle with indexing. The automatic Rotation Cycle includes the entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time!Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with spare parts & tools. -- 14-Section Clamp will produce 300 panels per shift; 20-Section machine, 500 panels per shift.