704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

BioMass

183 Results Found

704-841-2001

Call for Price

COMPLETE LOOSE BAGGING SYSTEM System includes: -- Feed Hopper 3 Yards Capacity. ( 87 Cu.Feet) -- 24 feet Incline Conveyor. -- GB Mechanical Bagging Scale -- Feeding Hopper 37 Cu.Feet with Stand. -- Packrite Xtrol Impulse Sealer. -- Motorized Bag Conveyor. -- Loaded on your Truck.

Call for Price

EXPRESS SCALE MCRS-180ELECHYD LOOSE BAGGING LINEComplete Loose Bagging Line including the Following; -- Hopper Stand and Support 37 cu' BF/GV/AUG -- GB Bag Fill Machine -- BF-14 Belt Feeder -- Bag Closing Conveyor 510-LP -- Fishbein Sewing Machine -- Hopper 87 cu' with Support -- Belt transfer Conveyor 27' -- Loaded on your Truck

Call for Price

LOOSE BAGGING SYSTEM "MCSRE"System includes and is supplied with: -- Hopper BF 87 Cu/Ft. and Support, Charging Hopper to Integrate with product Delivery Conveyor -- CON PD 24X24: 24 Feet Product Delivery Conveyor -- Hopper Stand BF: Hopper and Support 37 Cu/Ft. Surge Hopper for 5 GV Duplex Net Weight Bagging System -- GV-52 - DUPLEX GRAVITY/VIBRATORY TRAY: Duplex unit for (20) Bags/Minute -- Spout to Meet Customer's Bag -- CON 512: Bag Closing Conveyor. 12 Feet Long -- PACKRITE XROL: Heat Sealer with Extra Set of CO.Loaded on your Truck

Call for Price

MCRS is a Bagging System for mulch, compost, rock, or sand. This system is complete with a 2-yard product surge hopper, a 20' X 24" wide troughed incline product delivery conveyor with a cleated belt, an 8' bag closing conveyor, and a custom 7.5 HP Elec/hydraulic power unit. The system can fill bags by time and depth of stream or digitally with load cells.Standard construction carbon steel Powder Coated Industrial Gray(RAL 7046).The MCRS operation has been designed for one man to bag fill, bag close, and stack three bags per minute continually. -- The operator hangs bag #1 on the scale, hits the palm switch to close the CG spout, and automatically fills it. -- Bag #1 will drop once the timer times out onto the moving conveyor and hangs bag #2 into position, hits the palm switch, and starts the filling. -- The operator steps to his left. Bag #1 contact a wand switch and is in position underneath the impulse sealer. --The operator starts the bag into the impulse sealer. Once completed, bag #1 is then manually stacked. -- Bag #2 filled and waiting for the operator's return. -- Bag #2 is then released, and bag #3 hung. -- The process is then repeated.The Front End loader feeds the system. Consists of the following --infeed hopper --incline conveyor --dosing system --bag closing system:Bag Closing System Consists of a (CON 508) 8' long x 1' wide smooth top belt to take bags into aposition where a wand switch manually stops them. The bags are then prepared and enteredinto theImpulse Sealer (31103737610) Programmable Impulse Sealer for the repeated sealing of thermoplastic films such as polyethylene and polypropylene. This automatic single-impulse heat sealer is controlled by a plug-in transistorized circuit board and electronic timers. The timed closure ensures an even and consistent seal. --THE PRICE REFLECTS AN UPGRADE FROM THE IMPULSE SEALER TO A SEWING SYSTEM.The operator has hands free to handle the product quickly. This type of machine generally increases workers' productivity.The electric foot pedal is included for manual operation. -- Seal Length: 24" -- Seal Thickness: 8 mil -- Seal Width: 10 MM

Call for Price

FANUC - S430iW, ...RobotFANUC Robot for palletizing rectangular compressed bags.Specifications -- (6) Axes. -- Payload: 165 kG (255 Lbs). -- H-Reach: 2,643 mm (104"). -- Robot mass: 1,300 kG (2,860 Lbs). -- Complete with: Pendant control. -- Complete with: Gripper type arm and pallet gripper. -- Refurbished with (90) days Warranty. -- Buyer to install safety guards.NOTE: Machine was rebuilt is 2021.

Call for Price

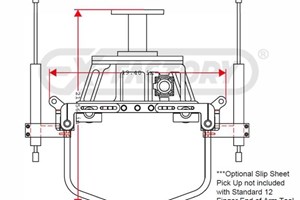

END ARM TOOLING FOR FANUC ROBOT -- Gripper Finger Type End Arm Tooling -- Design for Fanuc Robot Model S-430iW -- Loaded on your truck

Call for Price

FANUC - M-410I, ...Palletizing RobotFANUC M-410iC/110 Robot is a Palletizing Robot. It runs on the FANUC "R30iB" and "R30iB Plus" controller platform. With lighter payload, this Robot is designed to run faster than its bigger variants.This Robot was ordered and never installed, so it is "new" old stock.Max. payload: 110 kG (242 Lbs). -- Reach: 2,403 mm (94"). -- Axes: 4. -- Repeatability: +/- 0.5 mm. -- Robot Mass: 1,030 kG (2,270 Lbs). -- Floor mounted.

Call for Price

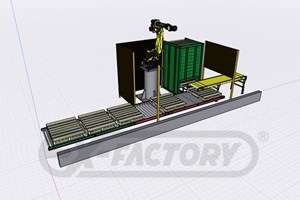

FANUC M410/160 iB ROBOT PALLETIZING SYSTEM Specifications: -- Complete with R-30iA Controller All Refurbished -- Pillow Bag Tooling -- 4-Axis control -- Mounted to a heavy-duty base -- 10 Feet Long Rubber Belt Conveyor -- (2) 5 Feet Motorized Pallet Conveyor -- (3) 10 Feet Motorized Pallet Conveyor -- Automatic Pallet Dispenser -- up to (14) 50 Lbs bags per minute -- Machine weight 4500 LbsAUTOMATIC PALLET STRETCH WRAPPING SYSTEMWULFTEC or LANTECH Stretch Wrapping System or Equivalent Not INCLUDED

Call for Price

COMPLETE FANUC 125I ROBOTIC PALLETIZING SYSTEM --System Includes the following: --FANUC M-410IB/160 Palletizing Robot with Controller and Stand --Robot will be tested --End of Arm Tooling to Pick, Fork Style, Picking 94 Lbs Concrete Bags --Master System Control Panel, 480 VAC 3PH & 24VDC Controls with HMI --Allen-Bradley Light Curtain with Safety Controller --Infeed Chain Drive Roller Conveyor 10 Feet --Pallet Hopper --Safety Fencing COST --20 Feet Exit CDLR Pallet Conveyor 52" Wide --System Integration / Programming

Call for Price

FANUC 165 Complete Palletizing SystemEquipped with and includes: -- FANUC 165 Complete with R-2000iA Controller with 600mm stand -- Pick-Up Arm Gripper Arm for pillow bag type -- 5 Feet x 24" Motorized In-feed Belt Conveyor -- (1) 10' Motorized Pallet Conveyor -- Automatic Pallet Dispenser -- Price includes Loading on your Truck

Call for Price

FLEXICON HOPPER/FEEDERSpecifications: -- Flexible Screw Approximately 12 Feet -- 7" Diameter -- Flights 6-1/2" -- Tube Diameter 7-1/2" -- Discharge Height 86 Inches -- Discharge Diameter 10 Inches -- 10 HP Motor -- Dimensions; 72" Long x 48" Height x 7-1/2" Depth -- Loaded on your Truck

FOLEY-UNITED 7460 910 Profile Knife GrinderSpecifications: -- Capacity: 12" Max. cutting circle x 12" W. -- Table size 7"; x 12"; x 34-1/2"; H. -- Table travel 12". -- Side clearance 5°, 10°, & 15°. -- Back relief angle 10° - 30°. -- Wheel O.D. 7" - 10", Wheel widths: 1/16", 1/8", & 3/16", Wheel arbor dia. 1-1/4".Equipped with: -- 2 HP - 2,850 RPM TEFC Wheelhead motor.Complete with: -- 40 mm (1.57") Dia. x 9-3/4" L Tool Arbor. -- Micro Precision Wheel Dressing System (MPDS), Swing-away.Dimensions of this specific machine 55" x 41" x 54" H.NOTE: No coolant pump.

Call for Price

FORESTECH ENTERPRISES - D-GR-1S: DryerDrum Dryer designed for a large Pellet plant; never put into production.Diameter (approx.): 12-3/4 Ft.Drum Length (approx.): 48 Ft.Dryer comes with Forge Tire but does not come with trunnion drives, which we can have manufactured.

GENERAL KINEMATICS Para-Mount II Single Deck Rectangular Vibratory Screener;Complete with the following features: --Model STM 96 X 20. --Carbon Steel. --Nominal screen size 96" wide x 20 long x 15" deep. --Designed for Trona mineral at a feed rate of 700 tons per hour at 80 pounds per cubic foot bulk density. --Driven by (2) 15 HP top mounted drives. --Current screen: Approximate 1" x 1" square openings. --Base mounted. --Overall dimensions: 290"L X 130"W X 90"H

Call for Price

GENOX V600 New Single Shaft ShredderIn Stock - Ready to Ship!Features --Shock Absorbing Gearbox that reduces stress on Drive Components -- 25HP -- Hopper Opening - 48" x 43" -- Rotor Diameter - 9" --Rotor Knives that can be used on four edges before replacement. --Durable Counter Knives that adjust to maintain cutter clearance --Quick Change Screens for accurate particle size control --Segmented Shredding Chamber Floor with Brass Guides --Twin Speed Hydraulics with an integrated air cooler --Stand Alone Electrical Control Panel with Siemens PLC Control System --Tested, Approved and Certified to the applicable CE safety standardsTypical Applications --Plastics --Wood --Cable --Paper --Aluminum --Foam --Textile

Call for Price

GENOX V800 New Single Shaft ShredderIn Stock - Ready to Ship!Features: -- Shock Absorbing Gearbox that reduces stress on Drive Components -- 50 HP motor -- Hopper Opening - 59" x 56" -- Rotor Diameter - 15.75" -- Rotor Knives that can be used on four edges before replacement. -- Durable Counter Knives that adjust to maintain cutter clearance -- Quick Change Screens for accurate particle size control -- Segmented Shredding Chamber Floor with Brass Guides -- Twin Speed Hydraulics with an integrated air cooler -- Stand Alone Electrical Control Panel with Siemens PLC Control System -- Tested, Approved and Certified to the applicable CE safety standardsTypical Applications --Plastics --Wood --Cable --Paper --Aluminum --Foam --Textile

Call for Price

GLOBAL BAGGER SYSTEMSpecifications: -- Support Structure 2" Tubular Steel -- Height 86 Inches -- Length 12 Feet -- Width top 60" and 90" Base -- Total Weight 1900 Lbs approx. -- Hopper Width 60" -- Hopper Length 106" -- Hopper Depth 44 " -- Capacity 3 Cu.Yards -- Hopper Conveyor Length 146 " -- Hopper Conveyor Width 25" -- Rubber Conveyor Belt 18" Wide -- Bag Clamp Air Operated -- Heat Sealer 24" capacity -- Bagging Capacity up to (200) Bags per HourOptions available, but not included; -- Weight Measure Scale -- Air Compressor -- Bag Stitching Machine -- One Year Warranty -- Loaded on your Truck

Call for Price

GRANUTECH-SATURN - BIG MAC, ...Used Car Crusher471 Detroit Diesel EngineSpecifications: -- Widely recognized as the industry standard, "Big MAC" flatteners combine high performance and low maintenance characteristics in a mobile auto crusher. The result is an unparalleled record for equipment performance: more than 90% of all "Big MAC" flatteners ever made are still at work, with machines built in the 70’s still in operation today. -- Featuring Heavy-Duty “quick-set-up"; hydraulic cylinders that can be quickly and easily raised for operation or lowered for travel, the "Big MAC" flattener meets the needs of today's mobile scrap processor. Offering a wide, opening for easier loading and larger capacities, the "Big MAC" is built to perform. Multiple automobiles can be easily compacted into dense bundles, reducing both onsite storage demands and transportation costs.Key features and benefits include: -- Quick setup design -- Air Compressor -- Waste oil collection tanks -- 6-Cylinder Tier III engine -- 6" Cylinder rods -- Hydraulic landing gear -- Heavy-Duty push bumper

GRANUTECH-SATURN - 62-40, ...Dual Shaft ShredderSpecifications: -- Motors: (2) 100 HP. -- Feed Opening: 62" x 40". -- Dual Shaft with independent Driven Shafts -- Includes: Feed conveyor & discharge conveyor, extra feed hopper; an extra pulley roller that is magnetized for exit end of discharge conveyor (current pulley roller in use is nonmagnetic). -- includes: (2) Service manuals and catwalk structure.

Call for Price

GRANUTECH-SATURN - GRIZZLY 80, ...Grinder Granulator Specifications: -- Rotor size: 77-1/2" -- Cutting diameter: 34-1/2" -- Main motor: 300 HP -- Speed: 321 RPM -- Number of knives: 50 -- Number of stationary knives: 10 -- Rotor type: STAREquipped with: -- Vibratory discharge conveyor -- Outfeed conveyor -- Crossbelt magnet -- Aspiration system -- Replaceable AR500 housing liners -- 3,500 sq/in. screening area -- Severe duty gearboxNOTE: New bed & fly knives on the machine, and new wear liners &new screens. Control panel will be completely rebuilt with a 500 Amp disconnect, a soft start and all the controls.